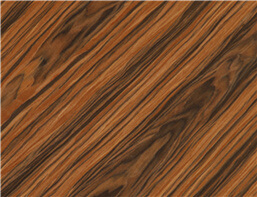

Engineered Wood Veneer

We produce standard 2500x640mm size engineered veneer in thickness 0.2mm to 0.6mm

Max length can be 3100mm,max width can be 1260mm

The species include Oak,Walnut,Ash,Teak,Maple,Cherry,Ebony,Wenge,Elm,Rosewood,Zebrano,Beech,Makore

Sapele,Mahogany,Apricot,Lacewood,Anigre,Bamboo,Bubinga,Cedar,Chestnut,Cypress,Padauk,Pine,Sycamore,Tulipwood,Burl,exotic.

EV Oak Veneer

EV Walnut Veneer

EV Ash Veneer

Washed Oak Veneer

EV Rosewood Veneer

EV Ebony Veneer

EV Wenge Veneer

Grey Oak Veneer

EV Teak Veneer

EV Cherry Veneer

EV Zebrano Veneer

EV Burl Veneer

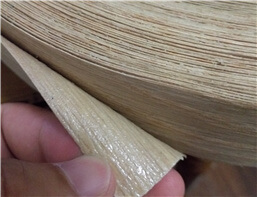

Paper Back Veneer & Fleece Back Veneer

We produce paperback veneer and fleece back veneer in thickness 0.2mm to 0.6mm

Which can be natural wood veneer or engineered wood veneer

The wood species include Oak,Walnut,Ash,Teak,Maple,Cherry,Ebony,Wenge,Elm,Rosewood,Zebrano,Beech,Makore,Sapele,Mahogany,Apricot

Lacewood,Anigre,Bamboo,Bubinga,Cedar,Chestnut,Cypress,Padauk,Pine,Sycamore,Tulipwood,Burl,exotic.

EV Fleece Back Veneer

Fleece Back Natural Veneer

Bamboo Veneer

Fleece Back Veneer Roll

Paper Back Veneer

Edge Splice Veneer

Paper Back Burl Veneer

Paper Back Woven Veneer

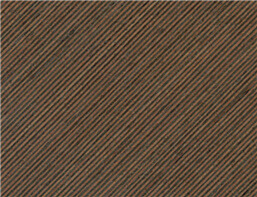

Woven Wood Veneer Sheet

We produce weave wood sheet in thickness 0.3mm to 0.6mm

Which can be natural wood veneer or engineered wood veneer,We can woven to different patterns according to clients request.

The wood species include Oak,Walnut,Ash,Teak,Maple,Cherry,Ebony,Wenge,Elm,Rosewood,Zebrano,Beech,Makore,Sapele,Mahogany,Apricot

Lacewood,Anigre,Bamboo,Bubinga,Cedar,Chestnut,Cypress,Padauk,Pine,Sycamore,Tulipwood,Burl,exotic.

EV Woven Veneer

Natural Teak Woven Veneer

Maple+Walnut Woven Veneer

3D Woven Veneer

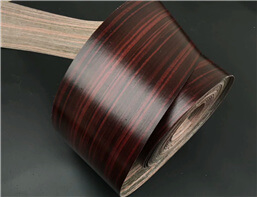

Edgebanding & Wrapping Profile Veneer

We produce 15mm to 300mm width edgebanding veneer and wrapping profile veneers in thickness 0.3mm to 2.0mm

Which can be natural wood veneer or engineered veneer.

The wood species include Oak,Walnut,Ash,Teak,Maple,Cherry,Ebony,Wenge,Rosewood,Zebrano,Beech,Makore,Sapele,Mahogany,Apricot

Lacewood,Anigre,Bamboo,Bubinga,Pine,Sycamore,Burl,exotic.

Natural Edge Banding Veneer

Wrapping Profile Veneer

UV Prime Edgebanding Veneer

Pre Glue Edge Band

Burl Veneer

Burl veneer can be natural veneer or engineered veneer in thickness 0.2mm to 0.6mm

The thickness of engineered burl veneer can be 0.2mm to 0.6mm

But the natural burl wood veneers in standard size 2500x600x0.2mm with paper backing

Walnut Burl Veneer

Mappa Burl Veneer

Golden Burl Veneer

Camphor Burl Veneer

Veneered Board

We also provide clients wood veneer faced plywood,veneered MDF,veneer faced blockboard and engineered wood flooring.

Veneer Faced Plywood

Veneer Faced MDF

Veneer Faced Blockboard

Engineered Wood Flooring

CONTACT OUR SUPPORT TEAM NOW !

FAQ

Q: What is engineered wood veneer ?

A: Engineered wood veneer is also known as reconstituted veneer,recon veneer,recomposed veneer,composite veneer,artificial veneer or man made wood veneer,chapas precompuestas,which is sliced from the pre-dyeing and pre-glued engineered wood blocks.

Q: What is the production process of engineered wood veneer ?

A: Raw wood veneers (Poplar,Obeche/Ayous,Basswood) —> Veneers Dye —> Veneer Patch—> Glue Pasting —> Press on the molds—> Form the engineered wood blocks—> Veneer slice —> Quality Grade Classify —> Packing

Q: What is the standard size of engineered wood veneers ?

A: 2500 x 640mm sheet is the standard size of engineered wood veneers. But you also can order the veneers length in 2050mm,2200mm,2800mm,3100mm,the maximum length can be 3400mm.Width standard is 640mm,but you also can buy 320mm,1260mm. Thickness can be sliced from 0.18mm to 0.8mm,and we also can saw the wood blocks to 1.5mm,2mm,3mm or any other thickness.

Q: How many kinds of engineered wood veneers ?

A: There are 3 kinds of engineered veneers you can find in Chinese market :

a) The first cheapest is the poplar 4x8ft size engineered wood veneer,which have only straight grains with original light white color.

b) The second is also poplar engineered veneers,in 2x8ft size,which have the very simple flat cut grains and quarter cut grains. They are much popular in India,Egypt and Pakistan market. Most of those engineered veneer is produced in Linyi region.

c) The third is the expensive quality engineered veneer,which made from Poplar,Obeche/Ayous,Basswood materials,have the various designs. They are made by Italy engineered veneer manufactuers and some Chinese quality manufacturers.

Q: What is the main factors to affect the price of engineered wood veneer ?

A:

a) Raw materials

Popular is cheapest raw mateirals, Obeche/Ayous is the commom materials to produce the quality veneers, Basswood is most expensive mateirals,which mainly used to produce Rosewood,Cherry,Burl veneer,Amara ebony and other special exotic designs.

b) Glue

The environment-friendly glue is expensive,like E1 grade. The common quality glue we use E2 grade.

c) Dye stuff

The dye quality is the most important factors for engineered wood veneers. Usually,there are 4 grades quality dye stuff.

1 grade is the cheapest quality,which will make the veneers color changed when apply some days later. Too many veneer doors maker and veneer furniture manufacturers show me the color changed veneers pictures to ask me “Can you help me ? Why my engineered veneers color change ?“. Cheap qualiy dye materials are the main reason.

2-3 grade is the common quality grade dye materials,which are used for almost all the engineered veneers manufacturers in China.

3-4 grade is the best quality dye materials for engineered veneers factory,which make the engineered veneers have the good color fastness, but they are mainly to used for Australia and USA markets. Some Australia and USA clients have a higher color fastness request for engineered wood veneers.

Q: What surface treatment can protect the engineered veneer color changed ?

A:

a) Just apply a primer

Just apply a primer if you want to save the costs.

b) Apply a primer first,then make the finishing

Make the finishing after primer will have a better isolation engineered veneers from air. So that can prevent the oxidation of veneer colors.

c) Paint Wax oil/UV protection oil on the engineered veneer

This will cost too much moeny,but have the best quality sureface.